Casting Metal Miniatures from Prince August Rubber Moulds: Part 4

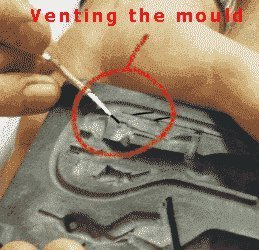

| STAGE#4 - Venting the Mould | |

|

After following the previous three tutorials you should be ready to vent the mould to get the metal into those hard to reach places like reins of horses or the bayonets on rifles. In the case of sprues surrounded by a frame you just cut a small vent from the problem area to this sprue. (Fig.1). Use a sharp modeling knife and a HEATED mould to get an easier cut. Make as many such vents as required to allow the metal into the problem area. |

|

|

(Fig.2) If the figure is not surrounded by a frame then always cut FROM the figure to the TOP of the mould. NEVER cut a vent to the bottom of the mould as the molten metal will only pour out through this. When you have Vented the mould to your satisfaction you repeat the previous tutorials to cast the figure with safety as top priority as always. |

|

(Fig.3) SUCCESS - The bayonet has filled this time. However a slight shift has occurred because the two halves of the mould were at a different temperature. Try to keep both parts of mould the same temperature to avoid this shift. (Fig.4)Now to remove you beautiful new cast figure from the mould. Carefully BEND the mould when removing the figure and you reduce wear and tear on the mould (which makes casting in future more prone to errors) and damaging the figure (after all your effort it would be a shame to ruin it with a moments carelessness). Filing the figure next tutorial. - see you then. |

|

|

Tips to remember:

|