Casting Metal Miniatures from Prince August Rubber Moulds: Part 2

| STAGE#2 - MELTING THE METAL | |

|

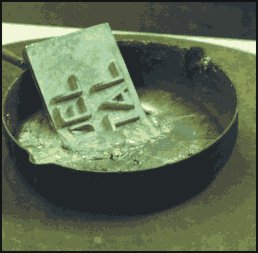

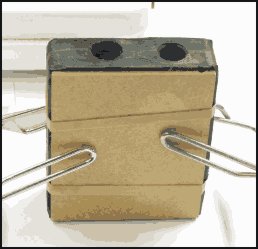

Melt the metal over the hob (Fig.1). Make sure metal is dry beforehand otherwise metal may spit and water escapes during melting. An electric hob is preferable for better control of the heat. Clamp moulds together (Fig.2) and make sure rough sides of boards are facing into the mould. Do not over-clamp the mould as two should be sufficient. Over-clamping can prevent the escaping of air through the mould. The quicker the air can escape the better the fill. This can often be overlooked and lead to gaps in the casting. |

|

|

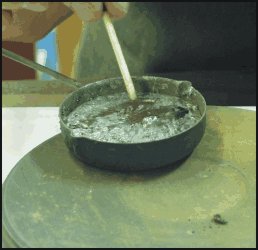

(Fig.3)Stir the metal with the back of a used match (just use the wooden end) before pouring the metal. You can tell when the metal is hot enough when the match end starts to brown and produces a small amount of smoke. If the match blackens and smokes heavily, the metal is too hot and will burn the mould. Push any slag (floating scum) away from spout of ladle you want to pour from to avoid getting the slag into the miniature body.

|

|

Tips to remember:

|

|